- mel@lasertec.au

- 6 Casting Way, Clyde North, VIC 3978

- 0432376066

Precision. Productivity. Profitability.

Experience the Power of Light – Schedule a Free Consultation

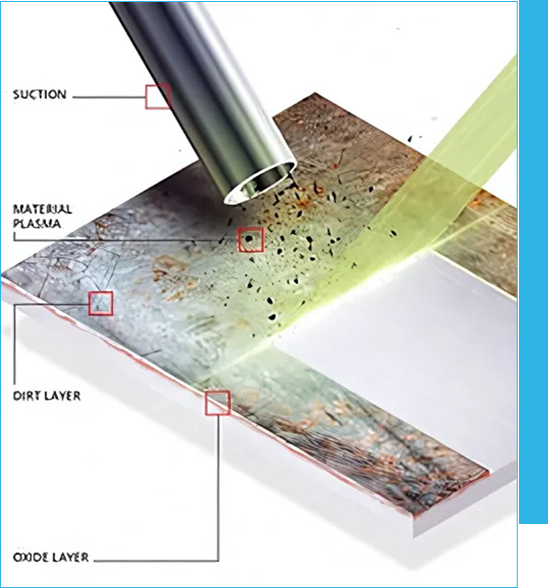

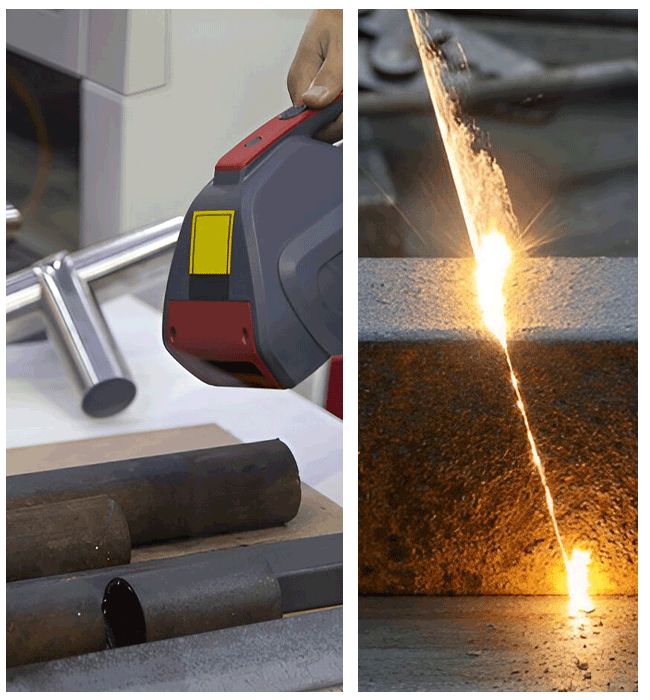

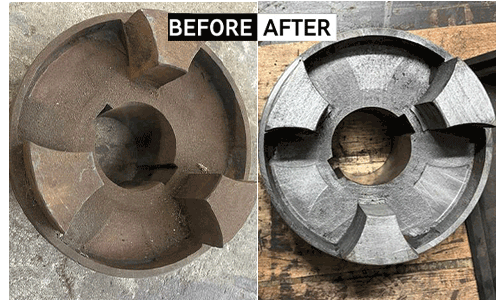

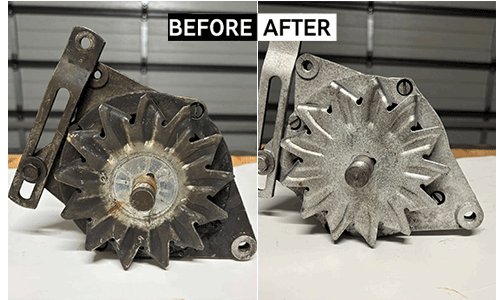

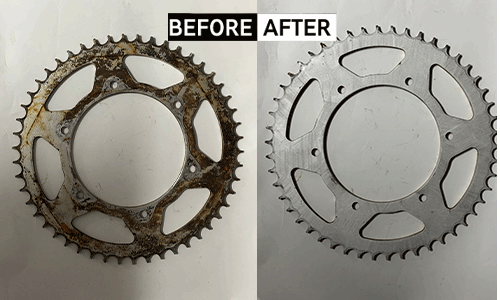

Laser cleaning is a safe, eco-friendly method for removing rust, paint, grease and surface contaminants without using chemicals, abrasives or water. It works by using a focused light beam to precisely clean surfaces without damaging the material underneath. This means no mess, no wear and minimal downtime. Ideal for industries like automotive, plastic manufacturing, marine, food production and many more. Laser cleaning offers a faster, cleaner alternative to traditional methods. At Lasertec Solutions, we deliver this advanced service on-site—efficiently, safely and with lasting results.

Lorem ipsum dolor sit amet, consec

Coating & Oxide Removal

Soot & Fire Damage Cleaning

Sterilization / Biofouling

Restoration of Machinery, Tools, Panels & Components

Surface Preparation (Preweld, Postweld or Paint)

Removal of unwanted contaminants like rust, paint, oil and coatings can lead to:

At Lasertec Solutions, we invest in

cutting-edge laser cleaning systems with the flexibility to expand as your

needs grow. Our modular approach allows us to add specialised machines—each

tailored for different materials, industries and cleaning challenges. Whether it’s

delicate precision parts or heavy-duty industrial equipment, we scale our

technology to deliver safe, efficient, and customised cleaning solutions.

Tell us about your problem and we can develop a solution.

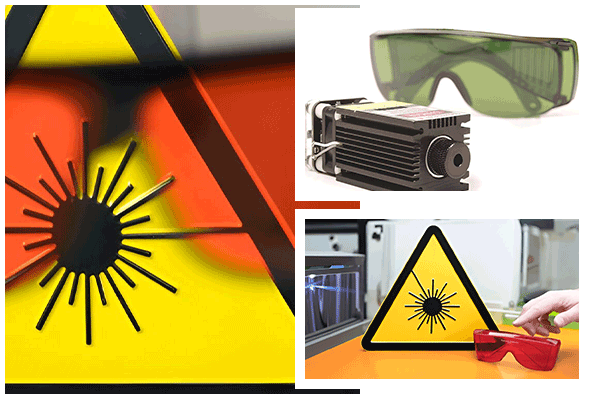

At Lasertec Solutions, maintaining a safe work environment is central to how we operate. We strictly follow Australian and international laser safety standards, including AS/NZS IEC 60825, to ensure all laser cleaning activities are conducted responsibly and safely.

Our operations are overseen by a certified Laser Safety Officer (LSO), responsible for managing risk assessments compliance with all safety protocols. Each cleaning task is performed in a dedicated laser-safe area, equipped with:

We use high-powered Class 4 laser systems, which require stringent controls to prevent accidental exposure. All personnel are trained in laser safety procedures and our equipment is operated only under strict supervision.

Lasertec Solutions is committed to exceeding industry safety expectations to protect our team, clients, and the environment. With us, safety isn’t just a requirement—it’s part of our culture.

At Lasertec Solutions, maintaining a safe work environment is central to how we operate. We strictly follow Australian and international laser safety standards, including AS/NZS IEC 60825, to ensure all laser cleaning activities are conducted responsibly and safely.

Our operations are overseen by a certified Laser Safety Officer (LSO), responsible for managing risk assessments compliance with all safety protocols. Each cleaning task is performed in a dedicated laser-safe area, equipped with:

Comparison Table: Traditional vs Laser Cleaning

Comparisons are indicative and may vary based on specific application.

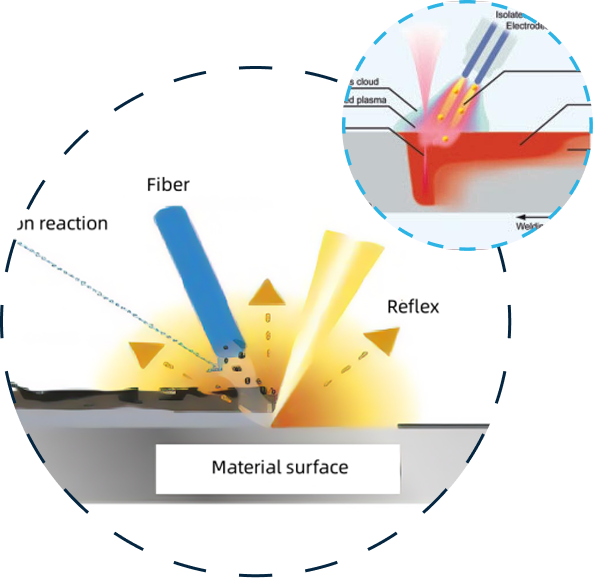

Laser cleaning is a non-contact method that uses highly focused laser beams to remove rust, paint, oil, coatings, and other contaminants from surfaces. The laser beam vaporizes the unwanted material without damaging the underlying surface, making it ideal for delicate or high-precision components.

Laser cleaning is effective on a wide range of materials, including metals (steel, aluminum, copper, etc.), stone, glass, and certain plastics. It’s commonly used for rust removal, paint stripping, weld prep, and mold cleaning on industrial components.

Yes. Laser cleaning is a non-abrasive process that preserves the integrity of your equipment. Unlike sandblasting or chemical methods, it does not wear down or damage surfaces. We also comply with Class IV laser safety standards and use proper protective equipment to ensure a safe operation.

Our solutions are ideal for:

Automotive and aerospace manufacturing

Heavy machinery and industrial equipment

Power generation and utilities

Electronics and precision engineering

Marine, oil & gas, and more

Laser cleaning offers several advantages:

No abrasives or harsh chemicals

Minimal waste and environmental impact

Precise and selective cleaning

Reduced maintenance and downtime

Higher safety and lower long-term costs

(Check our detailed comparison table above)

Laser cleaning produces minimal waste. Most contaminants are vaporized into gas or small particles, which can be captured with a simple vacuum or filtration system. It’s significantly cleaner and more eco-friendly than sandblasting or chemical cleaning.

In most cases, laser cleaning can be performed quickly and with minimal disruption. Depending on the scope, small components can be cleaned offsite, or larger equipment can be cleaned during planned maintenance windows.

We were struggling with rust and old coatings on precision dies. LaserTech Solutions delivered exceptional results. Their laser cleaning not only restored the tools but improved our surface preparation for welding. Turnaround time was quick, and quality control improved dramatically.

Our cleaning services are designed for delicate and efficient surface restoration, delivering exceptional precision and accuracy through advanced laser cleaning technologies.

At Lasertec Solutions, we go beyond surface-level cleaning to deliver real performance benefits for your business. Our advanced laser cleaning systems help you reduce operational costs, improve equipment longevity, and ensure consistent product quality.

© 2025 Lasertec Solutions All Rights Reserved. Powered by Codeadroit

Be the first to know about new arrivals and promotions