- mel@lasertec.au

- 6 Casting Way, Clyde North, VIC 3978

- 0432376066

Expert laser cleaning Melbourne services for rust, paint, and grime removal. We specialise in industrial laser surface cleaning that’s safe, precise, and eco-friendly. Perfect for machinery, metal, and more.

Experience the next level of surface restoration with Lasertec’s laser cleaning Melbourne services. This advanced technology offers a precise, non-contact method for removing rust, paint, and other contaminants without damaging the surface. Ideal for machinery, equipment, and delicate structures, industrial laser surface cleaning is eco-friendly, efficient, and requires no harsh chemicals. Whether you’re in manufacturing, restoration, or maintenance, Lasertec delivers a cleaner, safer, and smarter solution.

Lasertec provides expert laser cleaning services Melbourne businesses trust for precision and reliability. Our solutions are perfect for metal restoration laser cleaning, effectively removing corrosion, coatings, and residues without damaging the base material. Whether it’s for industrial equipment, structural components, or heritage metalwork, our laser technology ensures a clean, restored finish with minimal downtime and zero chemical use.

At Lasertec, we combine cutting-edge technology with years of expertise to deliver top-tier laser cleaning services in Melbourne. Our team specialises in safe, non-abrasive cleaning methods that protect surfaces while removing rust, paint, grease, and contaminants with precision. Whether it’s delicate heritage structures or heavy industrial machinery, our tailored solutions ensure outstanding results every time. With a strong reputation for reliability, quality, and eco-friendly practices, Lasertec is the go-to choice for metal restoration laser cleaning and industrial surface treatment across Melbourne.

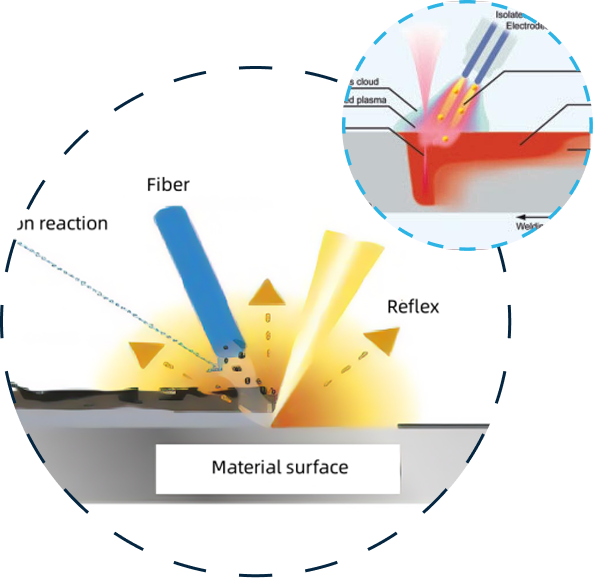

Industrial laser surface cleaning is transforming how businesses maintain their machinery and infrastructure. At Lasertec, we provide cutting-edge laser cleaning Melbourne solutions that are precise, eco-friendly, and highly cost-effective. Using focused laser beams, contaminants like rust, paint, and oil are removed without damaging the base material—eliminating the need for abrasive chemicals or extensive downtime.

Our industrial corrosion cleaning services are ideal for industries such as manufacturing, transport, and construction, where surface integrity and efficiency matter. As a trusted name in industrial laser surface cleaning, Lasertec helps companies reduce maintenance costs while supporting sustainable operations.

Laser cleaning is a non-contact method that uses highly focused laser beams to remove rust, paint, oil, coatings, and other contaminants from surfaces. The laser beam vaporizes the unwanted material without damaging the underlying surface, making it ideal for delicate or high-precision components.

Laser cleaning is effective on a wide range of materials, including metals (steel, aluminum, copper, etc.), stone, glass, and certain plastics. It’s commonly used for rust removal, paint stripping, weld prep, and mold cleaning on industrial components.

Yes. Laser cleaning is a non-abrasive process that preserves the integrity of your equipment. Unlike sandblasting or chemical methods, it does not wear down or damage surfaces. We also comply with Class IV laser safety standards and use proper protective equipment to ensure a safe operation.

Our solutions are ideal for:

Automotive and aerospace manufacturing

Heavy machinery and industrial equipment

Power generation and utilities

Electronics and precision engineering

Marine, oil & gas, and more

Laser cleaning offers several advantages:

No abrasives or harsh chemicals

Minimal waste and environmental impact

Precise and selective cleaning

Reduced maintenance and downtime

Higher safety and lower long-term costs

(Check our detailed comparison table above)

Laser cleaning produces minimal waste. Most contaminants are vaporized into gas or small particles, which can be captured with a simple vacuum or filtration system. It’s significantly cleaner and more eco-friendly than sandblasting or chemical cleaning.

In most cases, laser cleaning can be performed quickly and with minimal disruption. Depending on the scope, small components can be cleaned offsite, or larger equipment can be cleaned during planned maintenance windows.

At Lasertec Solutions, we go beyond surface-level cleaning to deliver real performance benefits for your business. Our advanced laser cleaning systems help you reduce operational costs, improve equipment longevity, and ensure consistent product quality.

© 2025 Lasertec Solutions All Rights Reserved. Powered by Codeadroit

Be the first to know about new arrivals and promotions