- mel@lasertec.au

- 6 Casting Way, Clyde North, VIC 3978

- 0432376066

Restore your equipment with precision using laser rust removal Melbourne services by Lasertec. Our advanced technology ensures safe and efficient rust removal from machinery, extending its life and performance without damaging the surface.

Laser rust removal Melbourne offers a fast, non-abrasive solution for restoring metal surfaces. Using advanced metal restoration laser cleaning, Lasertec ensures precise rust removal from machinery without damaging the base material. It’s the ideal method to restore corroded metal parts efficiently and eco-consciously.

Lasertec combines cutting-edge technology with expert service to deliver exceptional results. Our process is safe for delicate components and free from harsh chemicals. Trust Lasertec for reliable and long-lasting rust removal solutions.

Industrial Laser Cleaning Melbourne is a game-changing solution for heavy-duty rust and surface contamination. At Lasertec, we specialise in metal restoration laser cleaning that removes rust, paint, and other impurities with precision and care. Our process is ideal for industrial equipment, tools, and structural components, helping businesses maintain peak performance and extend asset lifespan. With zero chemicals and minimal waste, our service is both efficient and environmentally responsible.

Lasertec offers cutting-edge laser rust removal Melbourne, providing a fast, precise, and eco-friendly solution to restore corroded metal parts without damaging the base material. Our advanced laser technology safely eliminates rust, paint, and contaminants from metal surfaces, making it ideal for automotive, industrial, and restoration projects. Unlike traditional methods, our process is non-contact, chemical-free, and requires minimal cleanup, ensuring efficiency and sustainability. Whether you’re dealing with rusted machinery, tools, or vintage components, Lasertec delivers reliable results that extend the life and appearance of your metal assets.

Lasertec specializes in rust removal from machinery using advanced industrial laser surface cleaning technology that is precise, eco-friendly, and highly effective. Our laser systems are designed to restore corroded metal parts without damaging the base material, making them perfect for heavy-duty industrial equipment and sensitive mechanical components alike. Whether you’re dealing with rust buildup on factory machinery, automotive tools, or aged equipment, our team ensures a thorough clean with no need for harsh chemicals or abrasive methods. As a trusted provider of laser rust removal Melbourne, Lasertec offers a sustainable and cost-effective solution for long-term maintenance and machinery restoration.

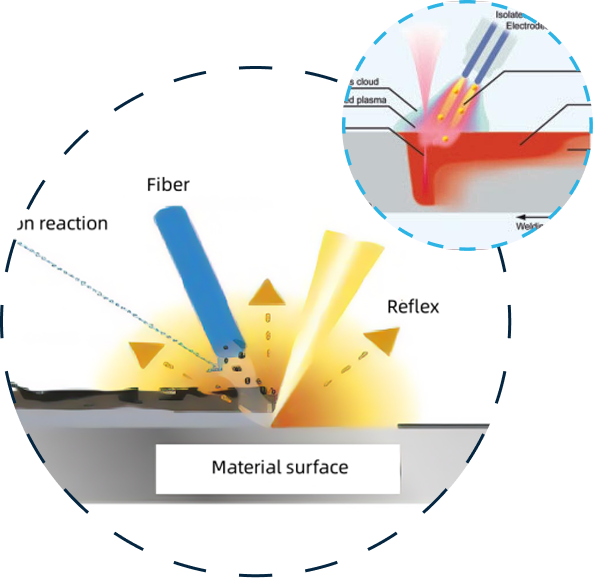

Laser cleaning is a non-contact method that uses highly focused laser beams to remove rust, paint, oil, coatings, and other contaminants from surfaces. The laser beam vaporizes the unwanted material without damaging the underlying surface, making it ideal for delicate or high-precision components.

Laser cleaning is effective on a wide range of materials, including metals (steel, aluminum, copper, etc.), stone, glass, and certain plastics. It’s commonly used for rust removal, paint stripping, weld prep, and mold cleaning on industrial components.

Yes. Laser cleaning is a non-abrasive process that preserves the integrity of your equipment. Unlike sandblasting or chemical methods, it does not wear down or damage surfaces. We also comply with Class IV laser safety standards and use proper protective equipment to ensure a safe operation.

Our solutions are ideal for:

Automotive and aerospace manufacturing

Heavy machinery and industrial equipment

Power generation and utilities

Electronics and precision engineering

Marine, oil & gas, and more

Laser cleaning offers several advantages:

No abrasives or harsh chemicals

Minimal waste and environmental impact

Precise and selective cleaning

Reduced maintenance and downtime

Higher safety and lower long-term costs

(Check our detailed comparison table above)

Laser cleaning produces minimal waste. Most contaminants are vaporized into gas or small particles, which can be captured with a simple vacuum or filtration system. It’s significantly cleaner and more eco-friendly than sandblasting or chemical cleaning.

In most cases, laser cleaning can be performed quickly and with minimal disruption. Depending on the scope, small components can be cleaned offsite, or larger equipment can be cleaned during planned maintenance windows.

At Lasertec Solutions, we go beyond surface-level cleaning to deliver real performance benefits for your business. Our advanced laser cleaning systems help you reduce operational costs, improve equipment longevity, and ensure consistent product quality.

© 2025 Lasertec Solutions All Rights Reserved. Powered by Codeadroit

Be the first to know about new arrivals and promotions